Disruption is facing manufacturing industries with increasing market competition and smaller lot sizes due to the consumers' demands for customized or personalized products. The Smart Industry concept is addressing disruptions and requires integration across operational technology functions and between operational and information technologies. The integration depends on using IoT technology, data orchestration, and analytics. Cloud computing is key in letting manufacturers to transform their factories toward Industry 4.0. Most of the implementation will be done at the device and require new infrastructure cloud capabilities.

CloudBackend is the solution of complex data management — a service that solves data availability, synchronization, data harvesting, security, and enables cloud computing in smart factories. The Singularity Database offers developers low latency cloud capacity and faster cloud applications and systems without the need of writing backend or networking code.

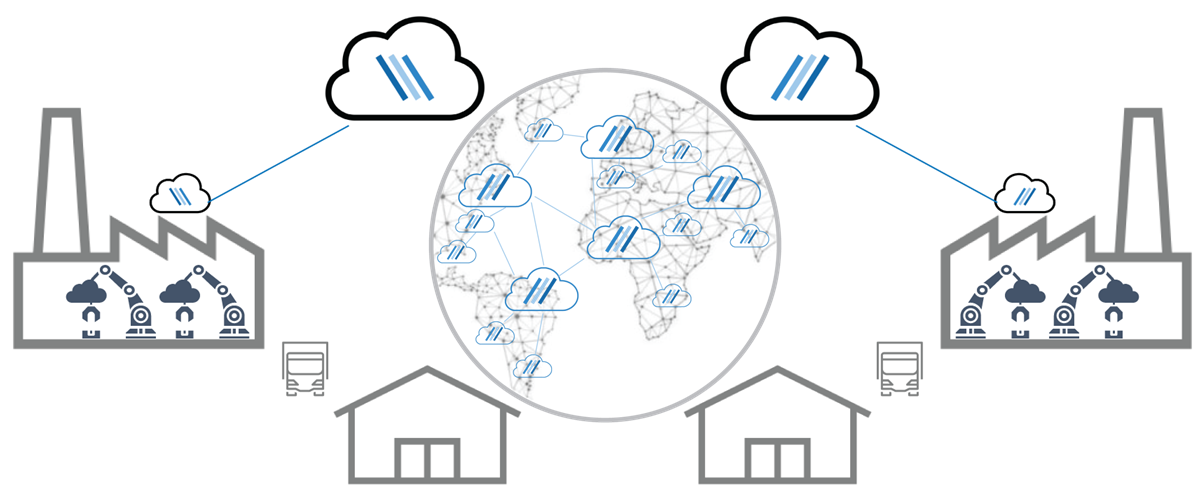

CloudBackend provides distributed clouds that constantly synchronize and keep its state while being nimble to fit inside inside IoT devices, in factory servers, and all the way up to public clouds. It is a very powerful end-to-end offering to developers that build industrial IoT solutions. The central features and benefits are:

- Collection and analysis of machine data

- Harvesting, analyzing and drawing conclusions from machine performance, enabling predictive maintenance and quality and feature improvements over time

- Harvesting, analyzing and drawing conclusions from customer usage, thereby enabling consultative services to machine owners that will improve their usage and create additional values in the manufacturers client relationship

- Aggregation and analysis of machine data with third-party AI/Machine Learning software

- Production line connectivity and synchronization of machines and even factories

- Enabling M2M communication and production line connectivity

- Establish a standardized way of handling data in every product or node and in the manufacturers' R&D offices

- Sharing configuration, 3D-models, and insights across machines, factories and potentially customers

- Improved app development – resulting in faster creation of better human-machine interaction interfaces and user experiences

- Modern apps for remote monitoring and control of key production data and machine performance data with rapid data access due to cloud computing

- Local cache of data in mobile apps that constant is kept in sync with cloud data

- Fast time-to-market with new apps that can interact with any cloud (any machine or even machine parts)